Search This Supplers Products:Yokohama fendersYokohama pneumatic fendermarine airbagsmooring buoysfoam filled fendersmooring ropes

Yokohama Type Floating Pneumatic Rubber Fender

- group name

- CNT Pneumatic Rubber Fender

- Min Order

- 1 piece

- brand name

- Jerryborg Marine,safe docking,safe mooring

- model

- JRBM-01

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash

- update time

- Mon, 18 Jan 2021 11:43:26 GMT

Paramtents

Product Name Pneumatic fender

Material nature rubber

Model JRB-PF-01

Fender Diameter 0.5-4.5 meters

Fender Length 1-9 meters

Standard ISO: 17357-2014

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Type I: Pneumatic rubber fender with chain & tyre net protective jacket

Type II: Sling type with rubber plate, rubber tube & ropes protective jacket

Type III: Ribbed type rubber fender

Type IV: Rope net type protective jacket rubber fender

Type V: Standard type without any protective jackets

Type VI: Hydro pneumatic rubber fender

1. Higher Safety and Reliability

2. No Deterioration or Variation in Performance

3. Higher Performance at Inclined Berthing

4. Most Cost Competitive System

5. Soft Reaction Force for Ship and Jetty Structure

6. Lower Mooring Forces under Rough Weather Conditions

7. Stronger against Shearing Force

8. Adaptable to the Tide

9. Simple and Low Cost Installation

10. Low Maintenance Cost

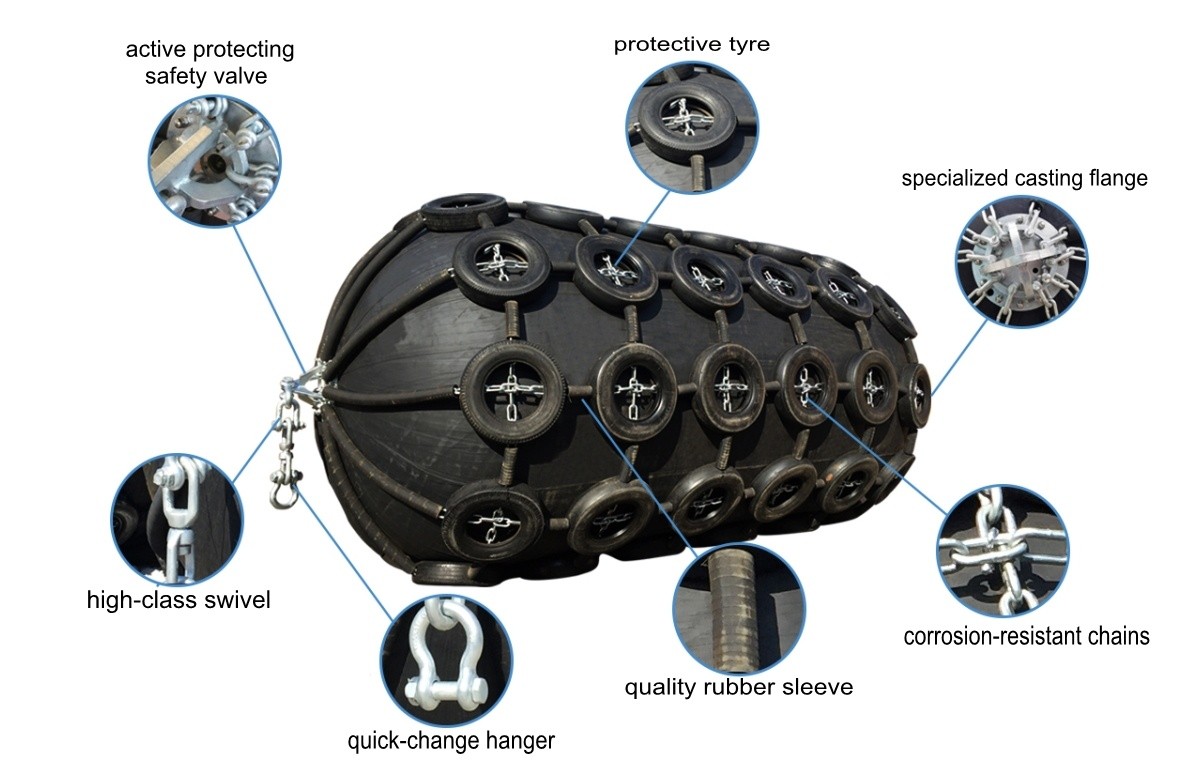

Yokohama type pneumatic fender is mainly consited of following spare parts

1. rubber fender body

2. used vehicle tires or used aircraft tires

3. protective rubber sleeves

4. metal hardwares like anchor chains, shackles, swivels, towing rings, etc

let's see below photo to know more about the sturcture of pneumatic fenders

Nominal Size diameter × length mm | Initial internal pressure kPa | Guaranteed energy absorption (GEA) | Reaction force at GEA deflection (R) | Hull pressure (Internal pressure) at GEA deflection (P) |

Minimum value at deflection 60 ± 5 % kJ | Tolerance ±10 % kN | Reference value kPa | ||

500 × 1 000 | 50 | 6 | 64 | 132 |

600 × 1 000 | 50 | 8 | 74 | 126 |

700 × 1 500 | 50 | 17 | 137 | 135 |

1 000 × 1 500 | 50 | 32 | 182 | 122 |

1 000 × 2 000 | 50 | 45 | 257 | 132 |

1 200 × 2 000 | 50 | 63 | 297 | 126 |

1 350 × 2 500 | 50 | 102 | 427 | 130 |

1 500 × 3 000 | 50 | 153 | 579 | 132 |

1 700 × 3 000 | 50 | 191 | 639 | 128 |

2 000 × 3 500 | 50 | 308 | 875 | 128 |

2 500 × 4 000 | 50 | 663 | 1 381 | 137 |

2 500 × 5 500 | 50 | 943 | 2 019 | 148 |

3 300 × 4 500 | 50 | 1 175 | 1 884 | 130 |

3 300 × 6 500 | 50 | 1 814 | 3 015 | 146 |

3 300 × 10 600 | 50 | 3 067 | 5 257 | 158 |

4 500 × 9 000 | 50 | 4 752 | 5 747 | 146 |

4 500 × 12 000 | 50 | 6 473 | 7 984 | 154 |

Nominal size diameter × length mm | Initial internal pressure kPa | Guaranteed energy absorption (GEA) | Reaction force at GEA deflection (R) | Hull pressure (Internal pressure) at GEA deflection (P) |

Minimum value at deflection 60 ± 5 % kJ | Tolerance ±10 % kN | Reference value kPa | ||

500 × 1 000 | 80 | 8 | 85 | 174 |

600 × 1 000 | 80 | 11 | 98 | 166 |

700 × 1 500 | 80 | 24 | 180 | 177 |

1 000 × 1 500 | 80 | 45 | 239 | 160 |

1 000 × 2 000 | 80 | 63 | 338 | 174 |

1 200 × 2 000 | 80 | 88 | 390 | 166 |

1 350 × 2 500 | 80 | 142 | 561 | 170 |

1 500 × 3 000 | 80 | 214 | 761 | 174 |

1 700 × 3 000 | 80 | 267 | 840 | 168 |

2 000 × 3 500 | 80 | 430 | 1 150 | 168 |

2 500 × 4 000 | 80 | 925 | 1 815 | 180 |

2 500 × 5 500 | 80 | 1 317 | 2 653 | 195 |

3 300 × 4 500 | 80 | 1 640 | 2 476 | 171 |

3 300 × 6 500 | 80 | 2 532 | 3 961 | 191 |

3 300 × 10 600 | 80 | 4 281 | 6 907 | 208 |

4 500 × 9 000 | 80 | 6 633 | 7 551 | 192 |

4 500 × 12 000 | 80 | 9 037 | 10 490 | 202 |