Search This Supplers Products:Yokohama fendersYokohama pneumatic fendermarine airbagsmooring buoysfoam filled fendersmooring ropes

What is the advantage of pneumatic fenders compared to traditional fenders ?

1. Safety and Reliability

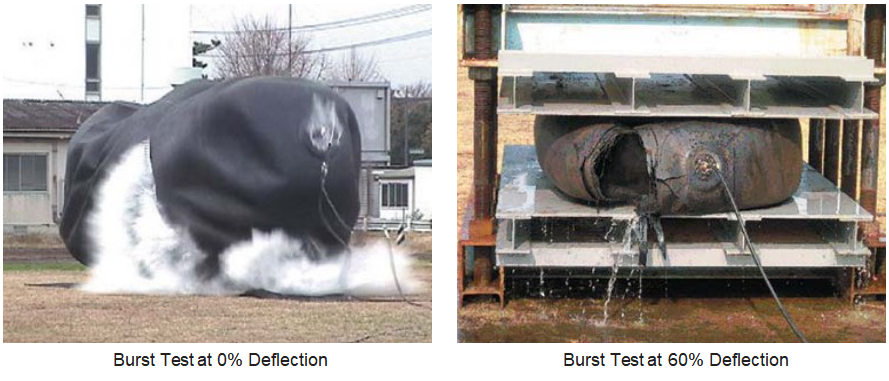

Yokohama Type Pneumatic Rubber Fenders are constructed of several layers of strong tire-cord, and are thus resistant to pressure and cutting. The safety factor adopted in the design of this fender is based on accepted theory and has been proven by extensive experimentation. large-size fenders are equipped with a safety valve to release the inside air in the event of accidental over-pressure.

2. No Deterioration or Variation in Performance

Jerryborg Marine Pneumatic Rubber Fenders utilize the compressive elasticity of air, therefore performance deterioration due to fatigue is absent. our Pneumatic Rubber Fenders also fully comply with the durability test required by ISO17357-1: 2014. Any reduction of the guaranteed energy absorption (GEA) is not accepted.

3. Advantages at Inclined Berthing

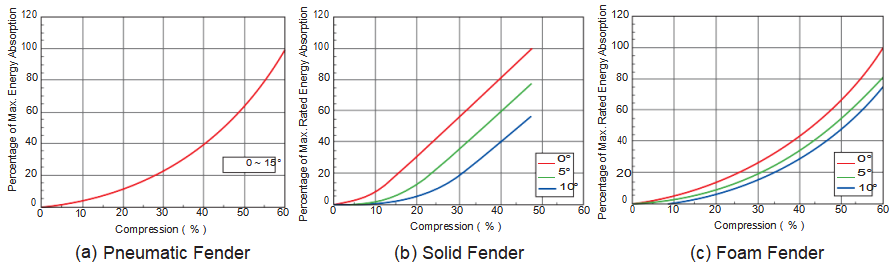

Yokohama Pneumatic Rubber Fenders, energy absorption does not decrease at inclined compression up to 15 degrees.

Reduction of Energy Absorption at Inclined Berthing for Pneumatic, Solid and Foam Fender

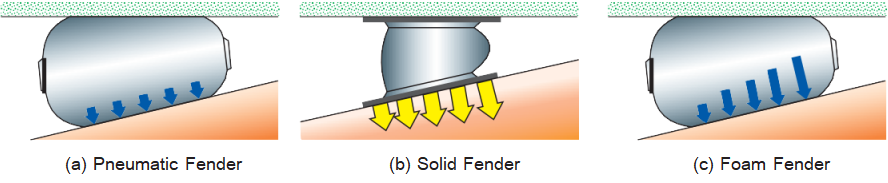

Distribution of load is also comparatively even because of the molecular freedom of air and high flexibility of the multi-layered cord-reinforced rubber membrane.

Load Distribution at Inclined Berthing for Pneumatic, Solid and Foam Fender

4. Most Cost Competitive System

The utilization of the compressive elasticity of air, unlike other fenders which need protector panels, provides completely uniform surface pressure on contact, making Pneumatic Rubber Fenders ideal. The surface pressure of the Yokohama Pneumatic Rubber Fenders is equal to the internal air pressure

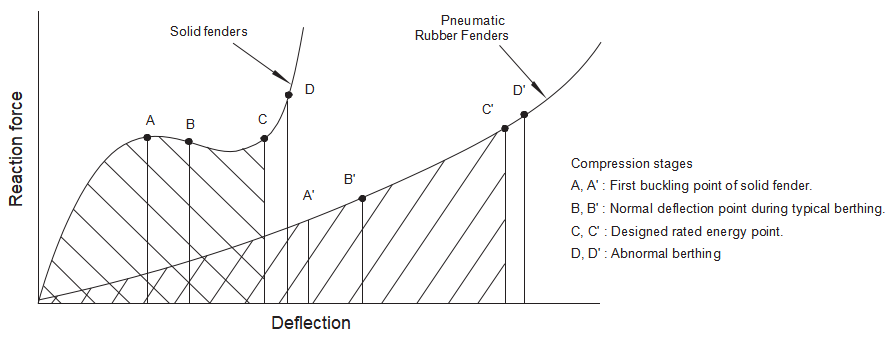

5. Soft Reaction Force for Ship and Jetty Structure

The reaction force of Pneumatic Rubber Fenders does not increase sharply, even under excess load conditions. Therefore, the Pneumatic Rubber Fenders perform well in such cases, and protect ships and mooring facilities. In contrast, the reaction force of solid rubber fenders, including buckling-type fenders, increases sharply under excess load conditions.

Soft Reaction Force for Ship and Jetty Structure

it can be seen that the Pneumatic Rubber Fenders are ideal as fender system because of gentle treatment of ships in below table.

Compression Stage | Comparison |

A, A' : Buckling point of solid fender | Pneumatic fender has lower reaction force and exerts lower hull pressure compared to the solid rubber fender |

B, B' : Normal deflection point | Pneumatic fender has lower reaction force and exerts lower hull pressure compared to the solid rubber fender |

C, C' : Designed rated energy point | Pneumatic fender has slightly higher reaction force only at this point |

D, D' : Abnormal berthing point | Pneumatic fender has lower reaction force and exerts lower hull pressure compared to the solid rubber fender |

6. Lower Mooring Forces under Rough Weather Conditions

the reaction force and deflection of Pneumatic Rubber Fenders do not easily reach the maximum because the reaction force increases slowly and allowable deflection is wide. Thus, the Pneumatic Rubber Fenders safely protect ships and mooring facilities even under rough weather conditions.

The use of Pneumatic Rubber Fenders sometimes eliminates the necessity of constructing a breakwater in the harbor. There are many studies and reports relating to

the above subjects.

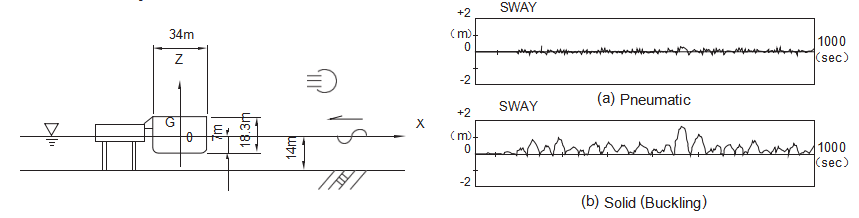

Model Studies on Ship's Movement with Yokohama Pneumatic Rubber Fender & with Buckling Fender

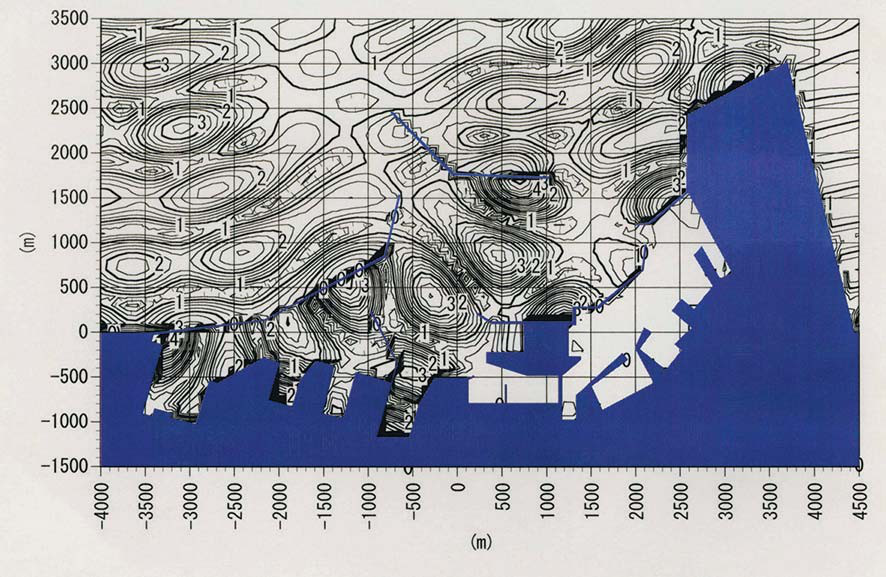

Calculation Results of Harbor Oscillations for Ship Motions moored along Quay Walls

7. Stronger against Shearing Force

Pneumatic Rubber Fenders are adequately reinforced using strong tire-cord to cope against such forces as well as internal pressure.

Stronger against Shearing Force

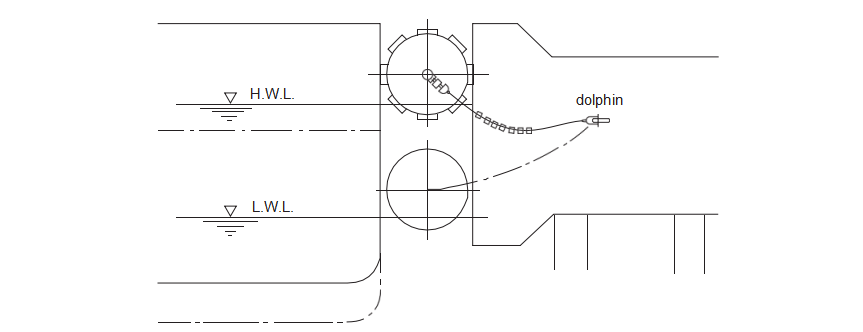

8. Adaptable to the Tide

Pneumatic Rubber Fenders basically float on the water in an unrestricted vertical plane corresponding to the tidal range and ship's vertical movement.

This means that energy absorption always takes place at the most suitable position.

Adaptable to Tide

9. Simple and Low Cost Installation

The weight of Pneumatic Rubber Fenders is supported by the water on which it floats. Therefore, the fender can be moored simply by means of a guy rope or chain, requiring minimal extra cost. It can be removed easily to a suitable jetty or quay when not in use, or transferred to another mooring point whenever required.

Φ1000×2000L-P50 Jerryborg Marine Pneumatic Rubber Fenders installed at a jetty

10. Low Maintenance Cost

Maintenance cost of Jerryborg Marine Pneumatic Rubber Fenders is very low. Although the internal pressure will vary with seasonal changes, the air leakage is so minimal that it is sufficient to check the air pressure only once a year. The chain net needs to be replaced only once in 3 or 4 years, depending on ambient conditions.

11. Shipping Cost Minimization

In order to minimize the shipping cost of Pneumatic Rubber Fenders, the fenders are usually packed and shipped in containers or on pallets in deflated and folded down state.

Vacuumed and Folded Down Condition for D4500×9000L-P80