Search This Supplers Products:Yokohama fendersYokohama pneumatic fendermarine airbagsmooring buoysfoam filled fendersmooring ropes

OCIMF Qualified Floating Marine Hose For Marine Tanker Loading Crude Oil

- group name

- Floating Hose

- Min Order

- 1 piece

- brand name

- Jerryborg Marine,safe docking,safe mooring

- model

- JRBMA-01

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash

- update time

- Sat, 09 Jan 2021 14:44:06 GMT

Paramtents

place of origin Qingdao,China

brand name Jerryborg

material Rubber

certification OCIMF 2007 GMPHOM 2009 Ship class BV

bursting pressure 105 bar

working pressure 21 bar

working temperature -20℃ ~ 85℃

MOQ 1 pcs

Packging & Delivery

-

Min Order1 piece

Briefing

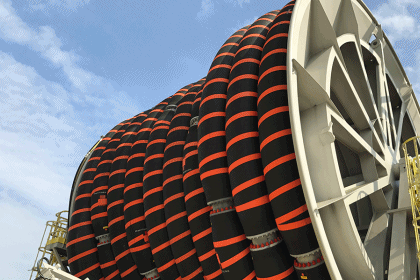

Floating marine hose is designed for the transportation of crude oil and liquid petroleum between ships and oil tankers.

Detailed

OCIMF Qualified Floating Marine Hose For Marine Tanker Loading Crude Oil

Floating marine hose

Jerryborg floating marine hose is produced according to OCIMF (Oil Companies International Marine Forum) standards. We are specializing in supplying floating marine hoses with single and doublecarcass designs for floating hoses and submarine hoses.

Floating marine hoses are subjected to manufacturing and testing requirements dictated by ISO 9000:2001 quality standards.

Jerryborg floating marine hoses are also designed and produced in full accordance to OCIMF standards.

Jerryborg floating marine hoses are designed to transport crude oil and petroleum products between loading and unloading vessels at offshore moorings systems.

Features of Floating Marine Hose

1. Independent foam floating sleeve prevents water absorption

2. Outer layer with excellent resistance to abrasion, aging, UV, and corrosive environments

3. Easy to install and maintain

4. Customized steel flanges

1. NBR compound synthetic rubber hose

2. Independent foam

3.Reinforcement: high tensile strength fabrics with helix steel wire

4. Cover: CR synthetic rubber

5. working temperature: -25℃ to 82℃

6. Safety factor: 5:1

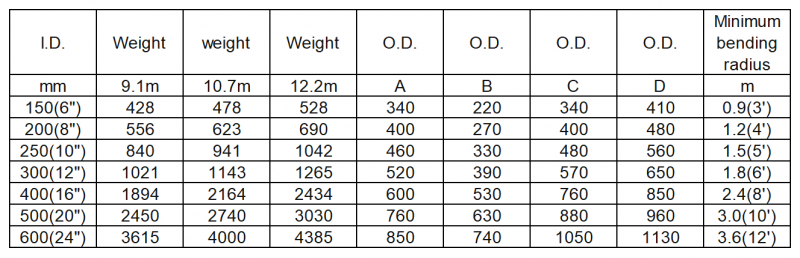

Floating Marine Hose Specification